(quoted from post at 00:37:26 05/01/17)

Excess current. Why? Because of bad info/advice generated from hearsay &/or miss-application application of good advice (good for some application other than yours) that this thread is full of. It may very well be that your supplied ceramic resistor is too large, but total deletion is not the way to correct that, if such is the case. The right way is to select an additional resistor value which will result in ~4 amperes, but less than 5 amperes through the coil when distributor is stopped so as to keep the module "on" (point closed like condition). You never said (as far as I could find) what the primary resistance of your 6v coil measures & even if you did, I wouldn't trust such measurement of that low value resistance (possibly less than 1/2 Ohm). As a possibility, let us assume that the coil is 0.47 Ohm & the OEM resistor is 1 Ohm, for a total of 1.47. 12.5 volts/1.47= 8.5 amperes and that will make for a glowing red resistor, short coil life, and short module life. All this is why I say, select resistance to result in ~4 amperes & less than 5 for steady state coil current. HINT: this will very likely be about 1.25 Ohms. Another point to mention is the those add-on resistors sold under the PN 10306 have been found to range about by as much as 3 to 1.....which in my book is useless.

don't know how to measure amps with the meter unless you pass the whole current through the meter?[color=red:7cf22da9a7]forget the dash ammeter for now as it not good enough for this task (if you want to work that, we can do later, but let us not muddy the waters now).

[/color:7cf22da9a7]

The ammeter on the dash was showing something like -20 to -25 while running for some reason, though 14 something volts across the battery posts.

I might have the panel ammeter wired backwards. The posts were not labeled and there were no instructions that came with it. Supposedly it's a replacement for the OEM but the OEM ammeter had no wires connected to it at all, and one of it's posts had long ago snapped off. With gauge installed in the dash right side up, I ran the alternator to the terminal on the right (carburetor side of tractor) and battery on the left, clutch pedal side.

Anyway if the amperage exceeds 10 amps it'll blow up my multi-meter.

Measuring ohms, the damn thing shows 0.8 or so when I hold the leads together. My dad said there's supposed to be a screw on the meter to zero it out but this is a cheap 5 dollar Harbor Freight multimeter and it doesn't have one. So if I just add 0.8 to the value, I assume it's somewhat accurate.

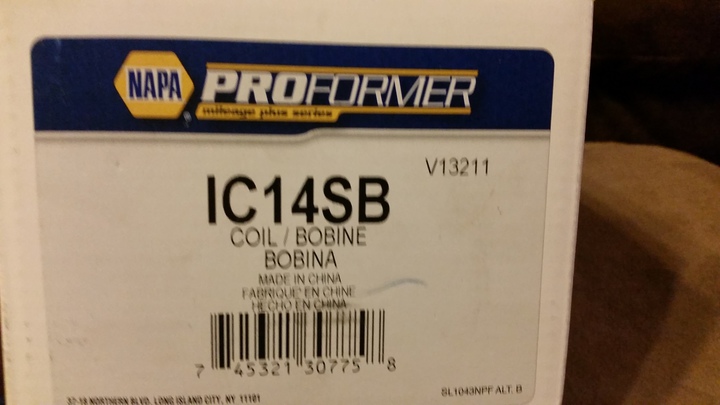

Tomorrow I guess I'll try the 12 volt coil which was giving me 2.8 ohms, including the extra 0.8 because of the crappy meter.

Will the resistance value on the tractor's original resistor have changed when it was glowing orange?[color=red:7cf22da9a7]yes. it will, as it is designed to increase resistance with temperature[/color:7cf22da9a7]

This would be a lot simpler if I knew what total resistance I need. Coil resistance plus additional resistor. [color=red:7cf22da9a7]didn't I just tell you that? Whatever it takes for 4-5 amperes. Now, I understand you want total Ohms, but I can't tell you that unless you can tell me the resistance of the red glowing resistor, which changes with temperature, at the operating conditions of 4-5 amperes. And you can't. From experience, I can say that is is ABOUT 0.5 to 0.6 Ohms, normal operating conditions. Your red one is ABOUT 1.7 Ohms. So, if you want 4.5 amperes at 13.8 volts (battery charging) and OEM resistance is 0.6 Ohms, then R= 13.8/4.5=3 Ohms total, less the 0.6=2.4 for coil plus extra resistance. So, if coil is 0.47 Ohms, the extra resistor is 1.9. If coil is 1.0, extra resistance is 1.4, etc., etc.

[/color:7cf22da9a7]

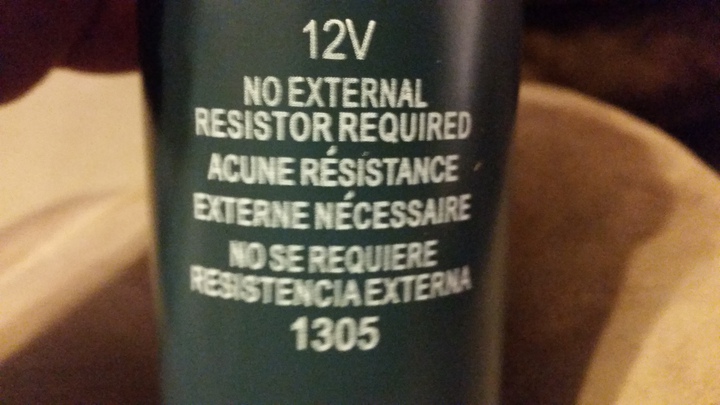

I'd tend to think a 12 volt coil made for a 12 volt system should be able to be wired directly to the ignition switch with no additional resistors required.[color=red:7cf22da9a7]in a perfect world! But square can front mount coils don't fit the "perfect world" and are "called" 6v or 12v and always need ballast resistance.[/color:7cf22da9a7][/b]