Howdy,

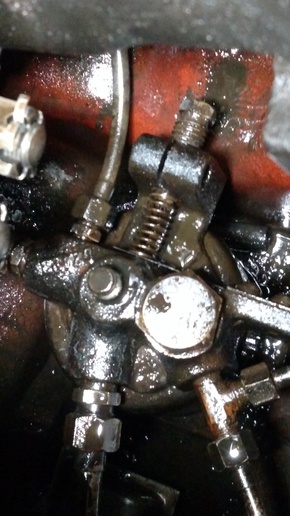

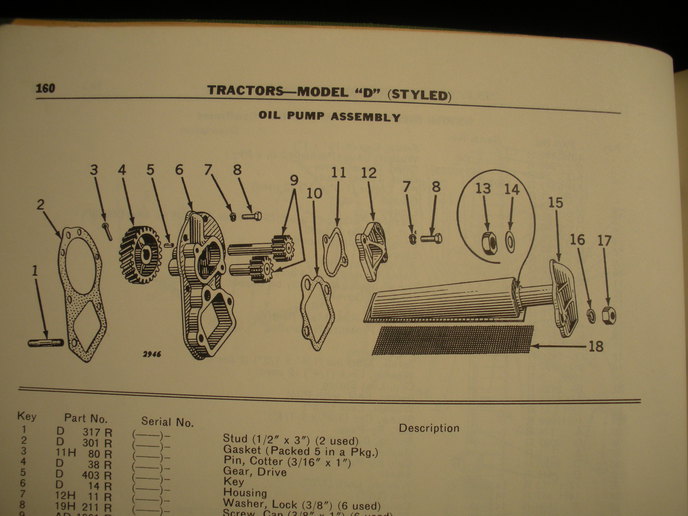

I have just gotten my Styled D running and it has low oil pressure. Just

barely above the Stop line at full throttle. Verified with another known

good gauge. I have been reading other posts about the same issue and did

some troubleshooting. I pulled the crankcase cover and blew air in the

oil pressure tube from a compressor. I took a video and posted it to

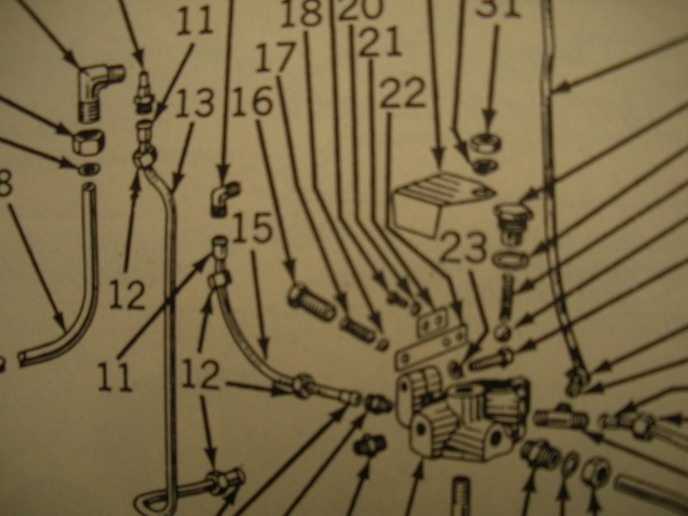

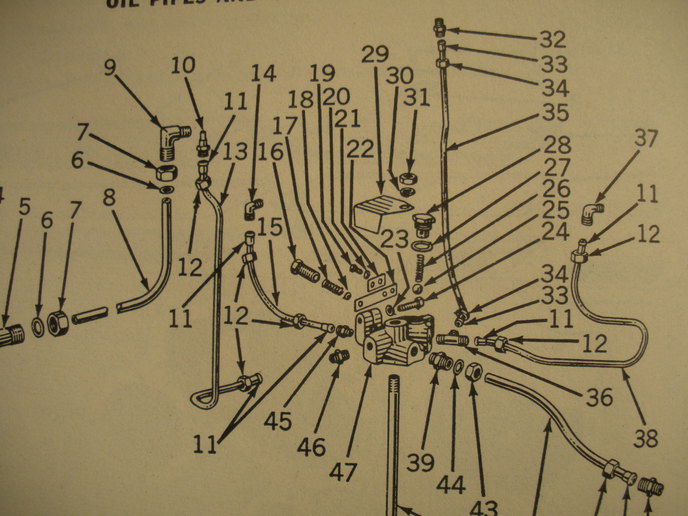

YouTube because this does not look right. Is this the dreaded warped oil

filter housing from over tightening? I'm not sure where it's leaking

from. First test at 20lbs and second at around 10-15lbs of air pressure.

What do the experts say?

Thanks for your help and advice!

(Please let me know if you can't view the video)

Low oil pressure troubleshooting video

I have just gotten my Styled D running and it has low oil pressure. Just

barely above the Stop line at full throttle. Verified with another known

good gauge. I have been reading other posts about the same issue and did

some troubleshooting. I pulled the crankcase cover and blew air in the

oil pressure tube from a compressor. I took a video and posted it to

YouTube because this does not look right. Is this the dreaded warped oil

filter housing from over tightening? I'm not sure where it's leaking

from. First test at 20lbs and second at around 10-15lbs of air pressure.

What do the experts say?

Thanks for your help and advice!

(Please let me know if you can't view the video)

Low oil pressure troubleshooting video