Sheeeesh young whippersnappers spending all your time fooling around with 2 wives probably drinking that girly diet beer instead of the dark brew and not use to doing a lick of real work. No wonder you're too weak to pull a couple of lipseals. Time for some edjumacation.

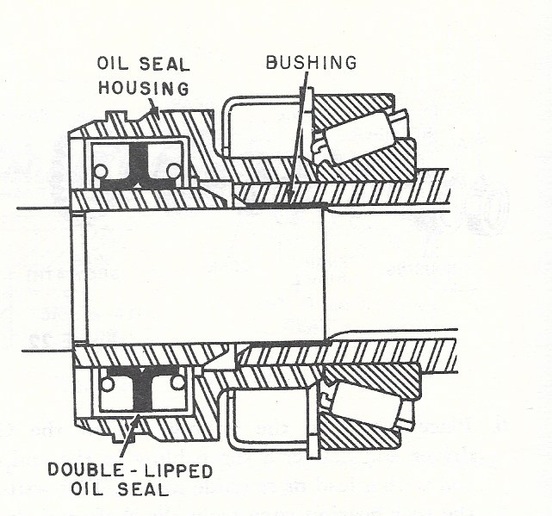

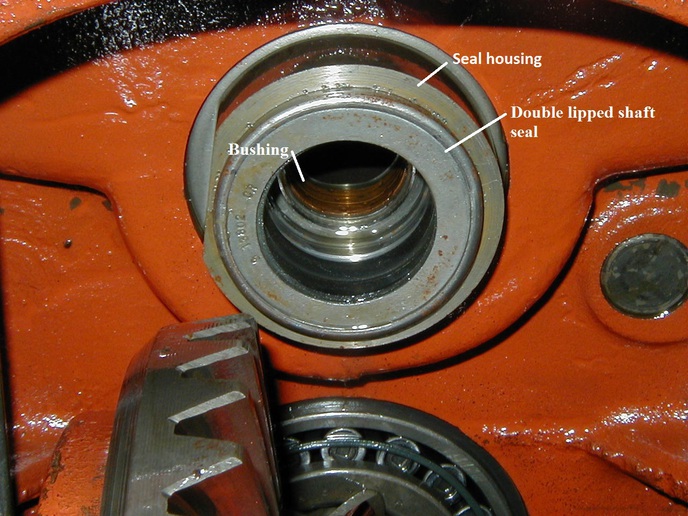

On 411B this is what we are working with. The brass bushing is pressed into the i.d. of the main shaft, the seal housing is pressed on the o.d. of the main shaft, the double lipped seal is pressed into the housing.

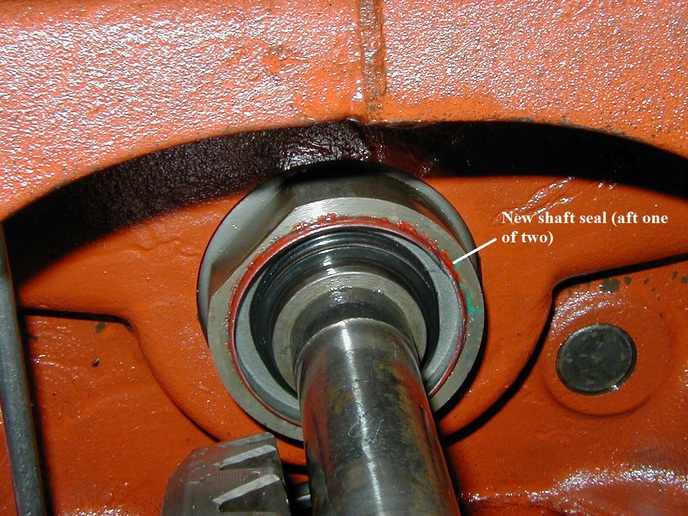

The factory double lipped seal is often replaced with 2 single lipped seals back to back with the lips facing opposite.

The seal housing press is a light interference fit so it can be removed to renew the brass bushing and then reinstalled. Housing reinstallation isn?t much fun. So using a slide hammer or other usual method of pulling the seals straight back is really iffy, a very good chance of pulling the housing along with the seal. The factory double lipped seal is very wide providing good grip on the housing and was staked.

The best way to pull seals in this type installation is with a pry bar like this pic. You can buy these pry bars in graduating sizes sets cheap. The width of the claw between the red lines should be wide enough that the sharp end can be placed inside the seal and the heel end resting on the metal part of the seal. Pry in different spots on the seal being careful not to score the housing. It is similar to pulling a nail with a claw hammer.

Factory seal in place, note the staking marks on the periphery. The seal sticks out of the housing a 1/8? or so. Replacement 2 seals will likely be the same so good idea to stake.

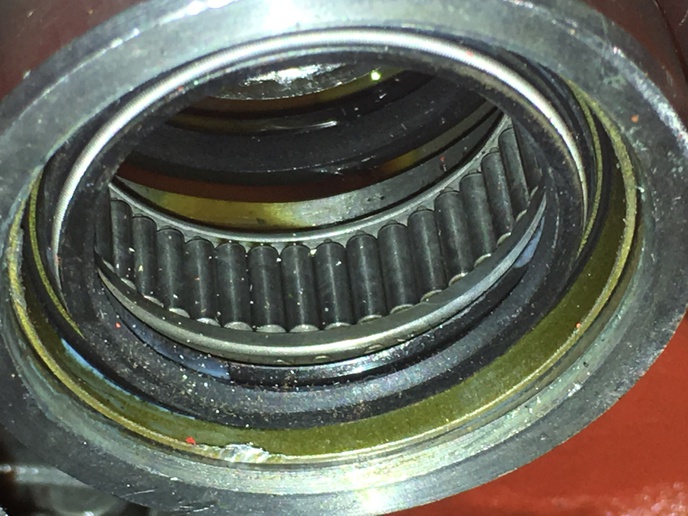

old seal in place You can just barely see the dimples in the brass bushing, that is for oil retention and wear indication.

To install new seals it is best to make up a long bar on your seal installer so you can start and tap the seals in place from the PTO opening, I use the 5/8? dia bar off a slide hammer for an extension. It?s really hard to start the seal straight from the top because the gears are in the way. If you start it crooked and try to tap it straight with a hammer it probably won?t seat properly and the next seal will make the seating worse. You might as well buy new seals and start over (don?t ask, many bad words, wrench throwing). You need good quality seals so they don?t flex so much on installation . I use National p/n 471192.

Dang after all the mental work writing this up, I think I?ll go rest up by wheelbarrowing some concrete and drinking some dark beer, after all it is Sat.

Joe